#TetherStudioStories: Sew Valley’s Studio and Production Space Helps Emerging Designers Thrive

#TetherStudioStories are an insider look at the spaces where creativity happens.

Sew Valley is a non-profit enterprise dedicated to providing designer-entrepreneurs with the space, equipment, and production services to build their brands.

Founders Rosie Kovacs and Shailah Maynard are UC DAAP alumni with years of experience developing and managing their own stylish brands like Brush Factory and Working Girls.

They’re using that expertise to help other local and regional designers bring their ideas to market by offering prototyping, sample making, pattern making, and small batch manufacturing for fashion and soft goods.

“We technically started in December in our old space in Camp Washington, setting up shop trying to find stuff, moving in. We awarded two free memberships just to get it going, see what works, what doesn’t."

Sew Valley Founders Rosie Kovacs (left) and Shailah Maynard (right)

“I started this organization because I was a struggling designer in the area looking for resources to affordably and efficiently develop my line.”

“I've coordinated my company's branding and art direction for seven years and have also worked on dozens of shoots for professional photographers,” says Shailah. “[I] feel confident in helping the emerging designers at Sew Valley get an idea of what it takes to create content for an e-commerce platform.”

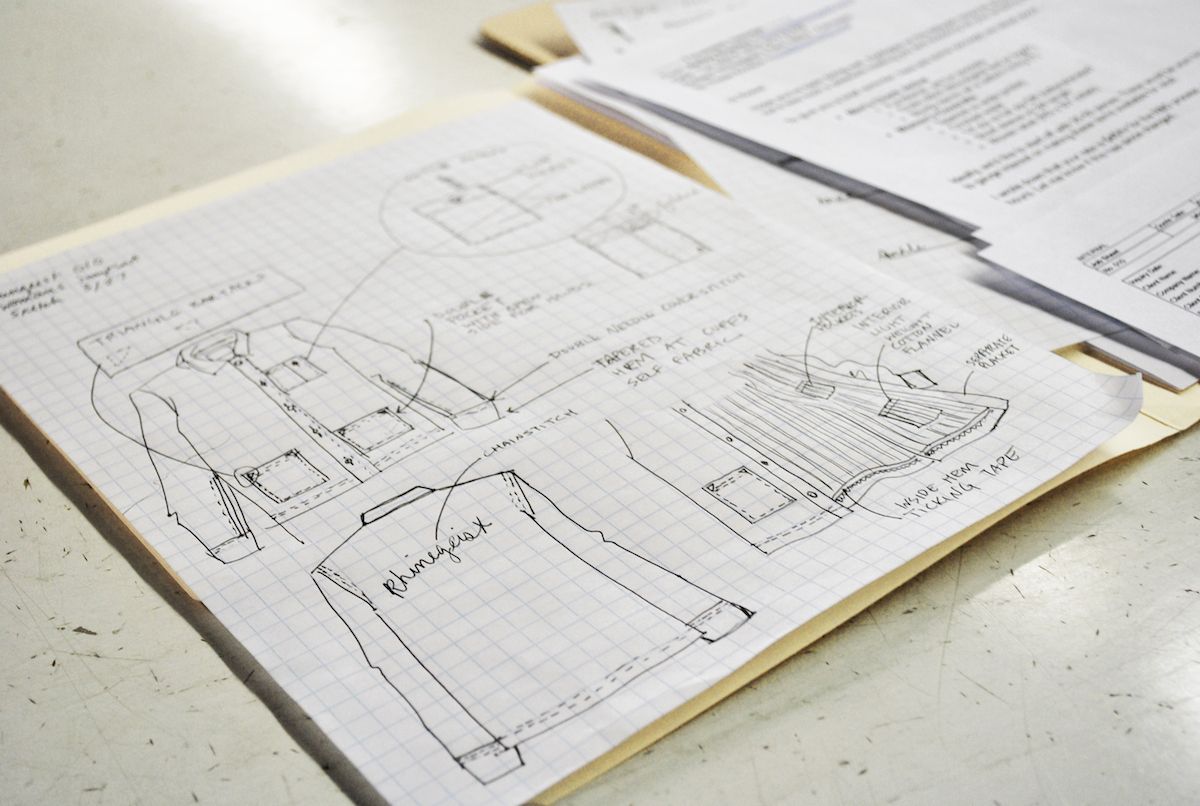

Rosie's sketch of workwear uniforms for Rhinegeist Brewery.

“For clients, typically we start out with a sketch and turn the sketch into a flat. We put that into the computer, then we work on prototypes. Prototyping is when you build a mockup testing the silhouette and functionality. For this [Rhinegeist] job we have flat patterns called blocks, which are standard measurements, and we can take that and change it based on your styling and details.”

Fashion designers Calle Evans and Tessa Clark share one of Sew Valley’s studios.

“We have a growing membership base where designers can move into our facility to use our space and equipment to work on their business. We’re the only facility of it's kind within the southwestern region of our state.”

“We have a variety of industrial sewing machines that specialize in one or two operations, domestic machines and various kinds of jigs and attachments. Pressing irons and steam tanks.Drafting paper, drafting weights, rulers, measuring tape, straight pins, many types of scissors and shears, tailors chalk, pens, sharpies, colored markers, post-its for fittings, Adobe Illustrator, Excel —the list goes on!”

The Northern Market studio sits next to an available space. Small studios are $150/month.

“We lucked out being able to move into a working facility, it was pretty turnkey. We took a tour just because we wanted to see how they worked and where they found their sewers—just doing a little research—then they came to see our old space and said we needed to move and they were like ‘we have space!’ If you put it out there, it comes to you. This is better than we could’ve ever imagined.”

Learn more and follow:

SewValley.org

@SewValley on Instagram

Facebook.com/SewValley